This class will cover DAF effluent. DAF effluent is the water left over from a unique process known as dissolved air flotation. Techange product is very useful on cleaning water, and we often use this to clean wastewater or old used unclean water. In this article, we introduce the process and discuss why it is important for environmental reasons as well as how various industries benefit from better management of their water. Water that remains after a dissolved air flotation process it offers a special technique to clean the dirty water by eliminating unnecessary particles and harmful molecules present in. They involve a step were throughout this process, small air molecules screw press are added to the water. These bubbles actually adhere to the grime and other particulate matter, allowing it all to rise up and out of your water. When the soil rises to its boundary, mud can be removed thus creating clear water. This is a crucial step in ensuring all the water that we consume throughout our day is safe and clean.

3e

One of the most significant and is essential in cleaning dewatering press for different factories, dissolved air flotation. Factories such as paper mills, food processing plants and chemical companies all routinely use this method to clean up their waste water. These factories can utilize the principles of dissolved air flotation and comply with regulations to safeguard our environment. This is so important to keep our water clean for all members of your community.

While the types and quantity of dirt in the water can vary based on what a factory produces, it also depends on what kinds of materials are used. Certain types of DAF effluent can be very challenging to clean and treat, particularly if heavy metals, acids or other hazardous chemicals are mixed in. They can cause a significant amount of environmental and human health damage because they are turned into harmful substances, which is why DAF effluent and screw press dewatering needs to be treated in this way. Knowing what is in the DAF effluent, when trying to determine a manner by which you can address such cleaning.

Treating DAF effluent and dewatering screw properly is extremely important in order to ensure the safety of such emissions back into the ecosystem. Another way of cleaning DAF effluent is by adding a coagulant, which acts as an agent to remove particulate and get rid of unwanted water materials. Thus, works by clubbing the dirt in a way making it easier to remove. More common are other approaches to water quality, such as using biological organisms or more elaborate techniques employing special filters and procedures. Regular quality checks of the water are also important to ensure safe standards and clean levels that protect our environment. Owing to this constant watch, factories are compelled into keeping their processes within limits prescribed by government regulations and thus contribute to some extent in making sure our water remains clean.

In the future, we should expect a lot of improvements to be made in DAF technology dewatering machine. New ideas and techniques to improve efficiency and effectiveness of dissolved air flotation processes are always being sought out by researchers, engineers etc. New technologies could include very small bubbles called special filters such as ultra filtration that might make water cleaning even more effective. For instance, factories may be able to reduce costs associated with cleaning wastewater and make industrial processes more sustainable by applying these methods as suggested by Techange for the removal of impurities from wastewater. While it may seem obvious to point out that we still need these things, the fact is they are not environmentally sustainable unless factories use better technology.

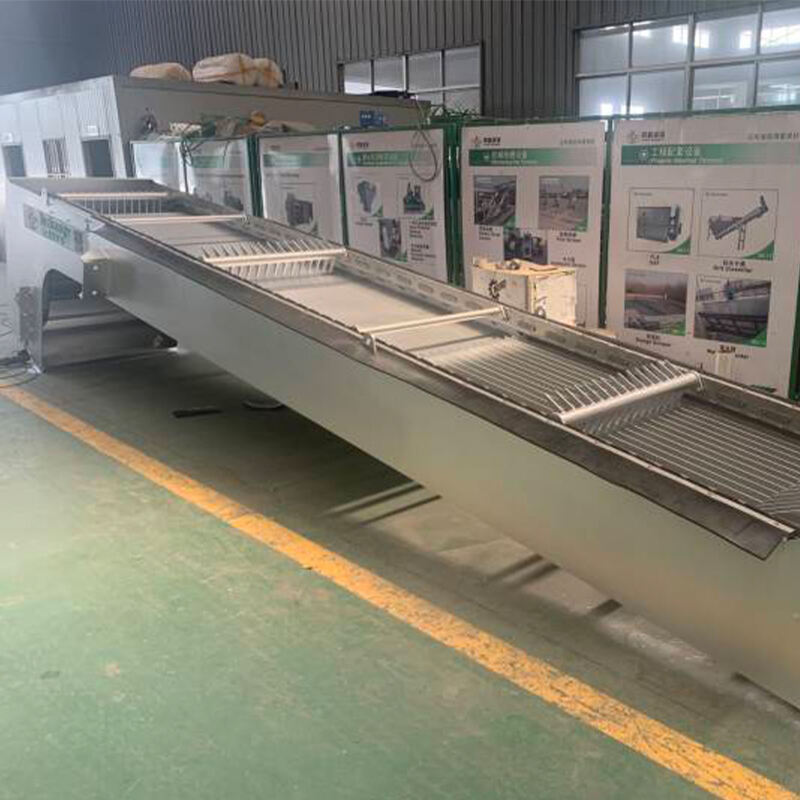

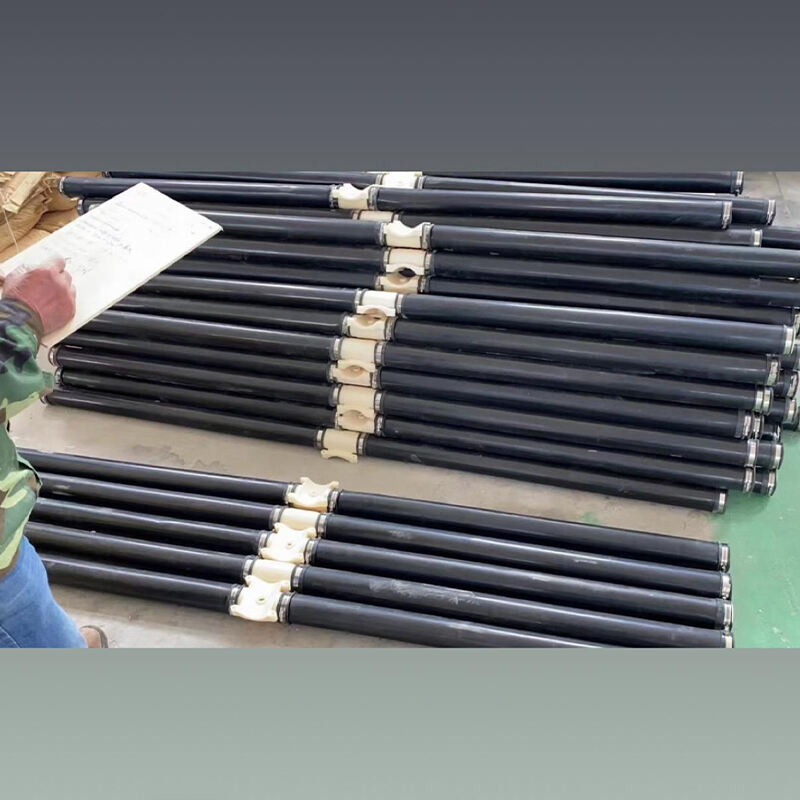

Jiangsu Techange Environmental Sci-Tech Co., Ltd. was established in the month of October 2008. specialize in the export wastewater treatment equipment since 2009. We a highly skilled manufacturer and designer of Daf effluent treatment equipment located in Yangzhou, Jiangsu, China. are well-known throughout Europe, North America Asia.

Our CNC bending laser cutting machines are latest in technology, allowing us to ship our products in time and to meet specifications of our customers.A lot of team members have more than a decade experience design research. They also have invented patents for the company.

All our equipment is ISO 9001, SGS, certified. Before the design of engineering, technical team will provide Daf effluent selection suggestion designer and the user of the project to make sure that the advantages of each item during the development of the project can be maximized.

We will meet your needs and the requirements relevant standards. We will plan Daf effluent machines and equipment in a high-quality manner, and we will control the quality of the purchased accessories.The product is covered by a one-year guarantee free. After that, customer is able continue receiving after-sales services for as long as they like and only pay for the cost.