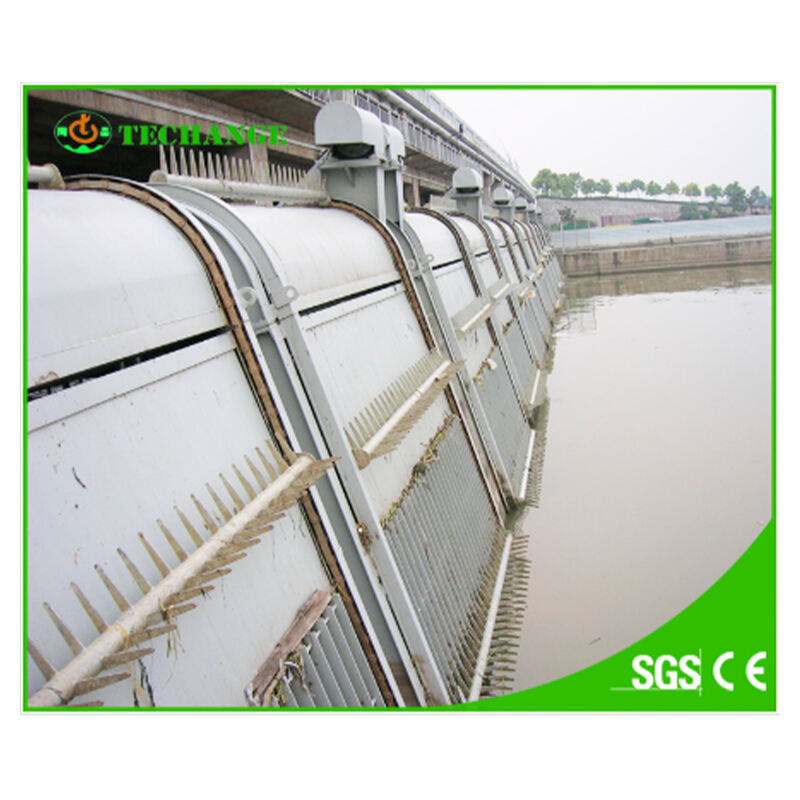

Mechanical course screens are in fact machines that have taken an essential role in the treatment of wastewater. They're built to get rid of solid items from wastewater like cloth, paper, metals and plastics. This primary stage is important to guarantee the water that it contains and can be utilized securely

If you would like to read more about how important those mechanical coarse screens are for your wastewater treatment, just take a look at Thomas Park describing them.

The mechanical coarse screens are one of the important stage in wastewater treatment plant. As the name states, they are designed to remove large solids from wastewater thus avoiding clogs and damage downstream. These screens are also because of which screen filters solid waste will be reduced and the treatment process resulting from water is more effective, efficient in terms of costs.

This also made the mechanical coarse screens great for uses in wastewater treatment facilities, among a number of other benefits. Not only do they help in reducing solid waste, but also save money by extending the life of other equipment through the treatment process. At the same, these machines need regular maintenance as well and that incurs additional or overall operating cost.

When it comes to the method of operation, there are many different types which a mechanical course screen can adopt although rotation drum screens do tend to be just one of most popular ones. Wastewater Passes Through to Capture Waste Particles via a Rotating Drum with Slots in This Process. Subsequently, the waste collected on the drum is stripped with a scraper. Static screens and inclined versions are a couple to the various kinds of mechanical coarse screen s that can be used in wastewater treatment.

However, for mechanical coarse screens to remain durable and function to some extent of performance always there need be scheduled maintenance actions. This includes maintaining the screens, checking bearings and replacement of minor components. Avoid overloading the machines will result in breakage. The machines provide reliability with consistent maintenance and can be run efficiently for long years.

Significant amounts of large particles can be removed from wastewater using mechanical coarse screens, though there are also other developed screening processes. In comparison to mechanical coarse screens, bar and microscreens have their own pros and cons. The screening method to be chosen is generally based on the particular needs of the wastewater treatment plant in order best to meet what it requires for solid separation.

To sum up, mechanical step screens are very important equipment during wastewater treatment. The importance of these filters is they work well in removing solid particles from water. Unraveling their functionality and maintenance requirement as well as comparing them to other types of screening systems points towards the fact that they are a key technology when it comes to providing clean, safe water for a wide range applications.

We will strictly follow the demands of your mechanical coarse screen and the applicable standards, carefully organize complete processing manufacturing of machinery and equipment of high-quality and control the quality of accessories that you purchase.When the product is approved, it enjoys a 1-year guarantee, free of charge. Also, after-sales service is offered for the life of product until warranty is up, and only the cost will be paid.

Our technical staff will make appropriate suggestions for the selection of mechanical coarse screen before engineering design. will help maximize advantages each product in construction of the projects.

Jiangsu Techange Environmental Sci-Tech Co., Ltd., established on October 8, 2008. Since 2009, have been specializing in exportation wastewater treatment equipment. We are a leading maker and designer of wastewater treatment mechanical coarse screen that is situated in Yangzhou, Jiangsu, China. are well-known throughout Europe, North America and Asia.

Our CNC laser cutting bending machines among the most advanced technology, which allows to provide our products schedule according to the customer requirements.Our team is comprised of highly skilled experts with advanced degrees in environmental science, engineering, and other related fields. Many team members have over a decade of experience working in research and development. have created numerous patents for our company.