Tel: +86 17715878828

Cellphone & WhatsAPP:+86 17715878828

Email: [email protected]

Product details :

Comparing with the other devices (belt filter press , centrifugal machine), TECHANGE Volute type sludge dehydrator has many advantages such as energy-saving, capable of working 24/7, fully automation ,lower polymer consumption , achieve a dry matter content of 15%-70%, minimal flush water consumption, minimal maintenance & operation cost , minimal noise, etc. Suitable for any type of sludge, for example, sludge from municipal, beverage, slaughter breeding, printing and dyeing, chemical, oil, paper making, pharmaceutical etc.

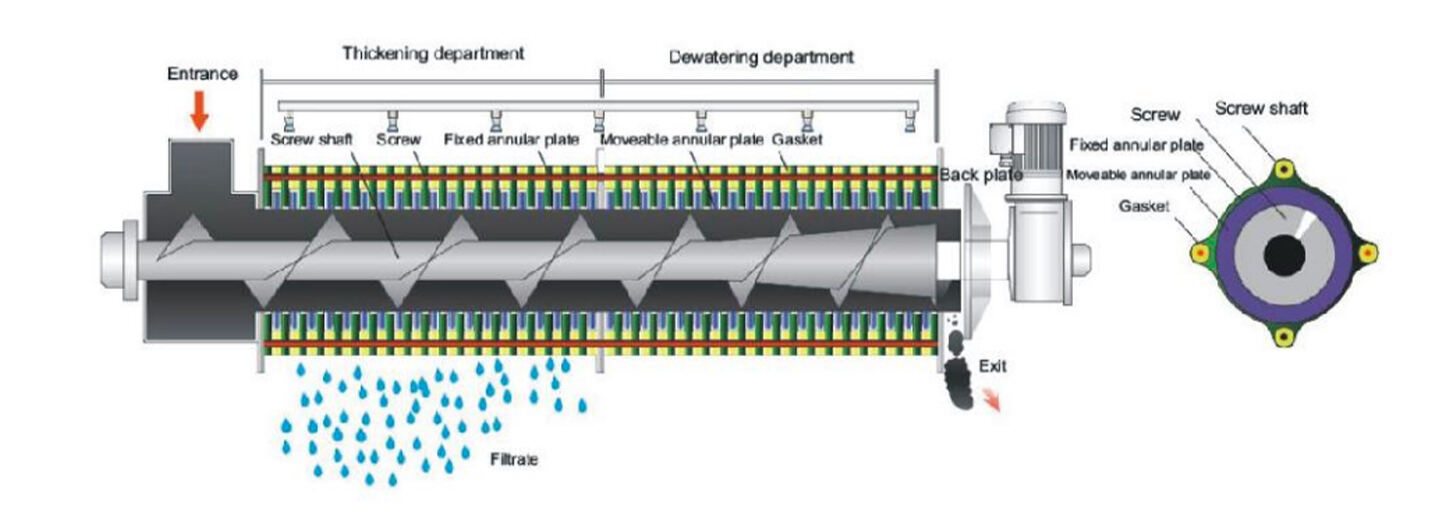

Working Principle:

Sludge will be transported to the dewatering department after being thickened in the thickening department. In the advancing process, great pressure has been produced because of the gradually decreasing filter spacing and screw distance, and the back platen clogging. Then the volume decreases continuously , and the purpose of fully dewatering will be achieved.

Benefits of Volute Screw Press:

Low energy consumption

Simple installation and operation

0.5-2%sludge at inlet,15-20%sludge at outlet

Low noise and vibration levels

Wide use applications

Automated mode

Affordable spare parts

Low transport weight

Low polymer consumption

Capable for working 24hours

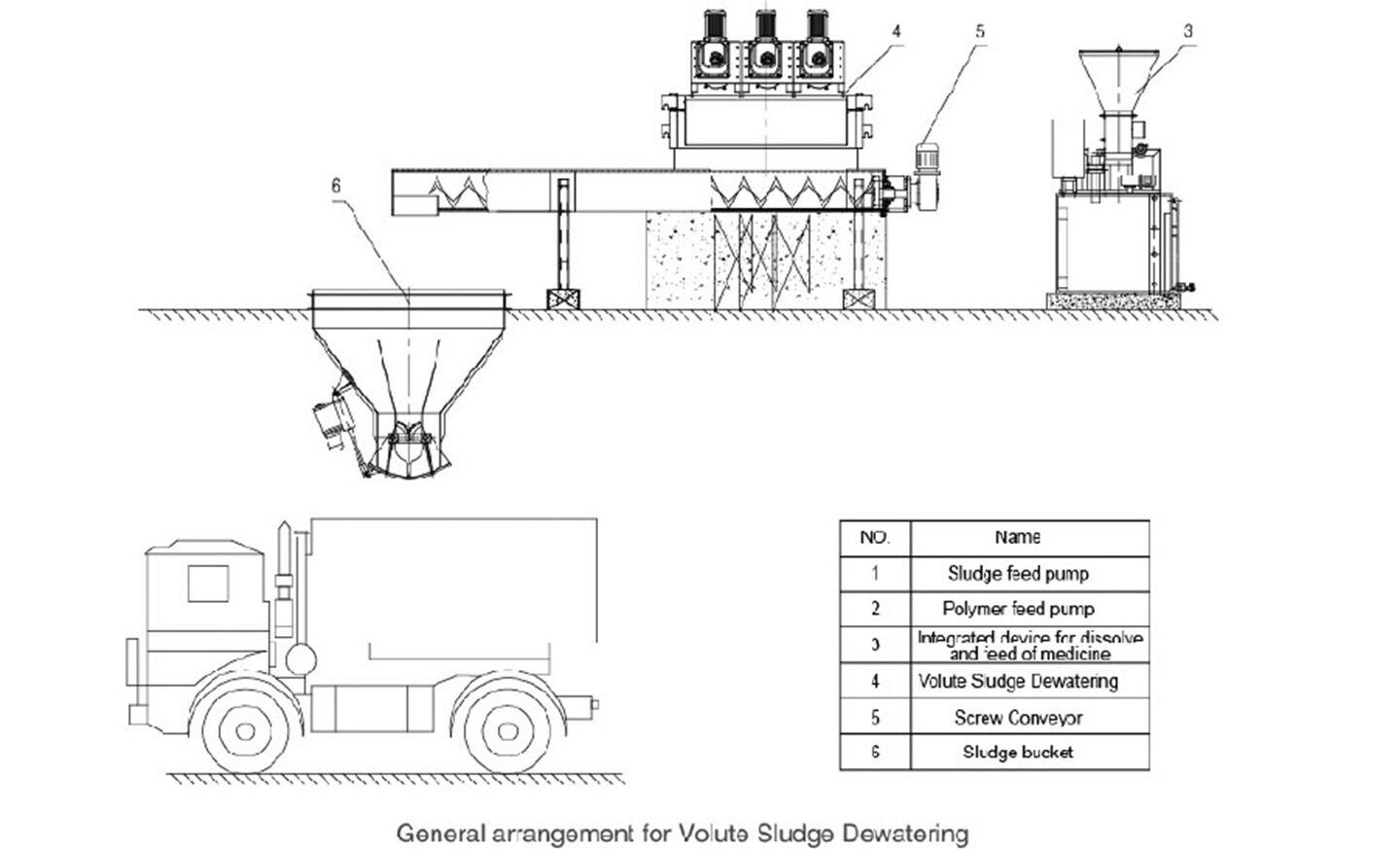

Process flow diagram :

Technical specification

| Model | DS CAPACITY (kg/h) | Dimension (mm) | N.W (kg) | Run Weight (kg) | ||

| L | W | H | ||||

| MYDL101 | 5-7 | 1850 | 740 | 1040 | 220 | 315 |

| MYDL131 | 10-14 | 2000 | 785 | 1040 | 250 | 395 |

| MYDL201 | 15-20 | 2510 | 900 | 1300 | 420 | 540 |

| MYDL202 | 30-40 | 2560 | 1050 | 1300 | 550 | 660 |

| MYDL203 | 45-60 | 2610 | 1285 | 1300 | 700 | 1010 |

| MYDL301 | 50-70 | 3330 | 1005 | 1760 | 900 | 1300 |

| MYDL302 | 100-140 | 3530 | 1290 | 1760 | 1350 | 2000 |

| MYDL303 | 150-210 | 3680 | 1620 | 1760 | 1900 | 2700 |

| MYDL304 | 200-280 | 3830 | 2010 | 1760 | 2500 | 3600 |

| MYDL351 | 100-120 | 4005 | 1100 | 2130 | 1100 | 2000 |

| MYDL352 | 200-240 | 4390 | 1650 | 2130 | 2100 | 3250 |

| MYDL353 | 300-360 | 4520 | 1980 | 2130 | 3100 | 4600 |

| MYDL354 | 400-480 | 4750 | 2715 | 2130 | 4100 | 5700 |

| MYDL401 | 130-160 | 4680 | 1110 | 2100 | 2200 | 4200 |

| MYDL402 | 260-320 | 4960 | 1760 | 2100 | 3500 | 6000 |

| MYDL403 | 390-480 | 5010 | 2585 | 2100 | 5500 | 8000 |

| MYDL404 | 520-640 | 5160 | 3160 | 2100 | 7000 | 9500 |