This is because solids are heavier than liquid, therefore it work as separation of solid to liquid. This results in the fact that while we blend them together, the solids that are heavier will sink and the lighter liquid is going to riseUTERS. There are multiple ways how we can extract these components, split them, and end up with a clear liquid. The three most popular mechanisms to accomplish this are roll-up, filtering and spinning.

It is a pretty straightforward technique of sitting for some time the mixture settled. When we do that, the dense solids go to the bottom of our container and so it boiled on top. This is analogous to the way in which sand separates from a faucet glass of water. Filtering involves putting a filter with small enough holes, like mesh or cloth to grab the solids while letting liquid go through. That way solids do not migrate back into the liquid. A machine spins the mixture rapidly in a process called spinning (a more advanced method). Which in turn creates a force that make the solids separate from the liquid faster.

Now that we understand solid-liquid separation, let us delve into a few ways in which this process can be more efficient and effective. One way to assist with this is by using flocculants. These are chemicals responsible for gluing together the smallest particles. They are felted together and create blocks of felting that can be loosened easily. In the case of water treatment plants, flocculants are used to purify dirty bodies of water by removing unwanted particles.

How well we might separate solids from liquids depends on a bunch of factors ~ The size of the particles is one key factor to consider. Comparatively speaking, smaller particles may be harder to separate due to likelihood of them staying in the liquid. So, we must add extra techniques to help us remove them. Another important factor is the solids portion of mixture. Too many solids would make the separation process less efficient, and in some cases may screw up your day_pesky problems

Solids and liquid those we are dealing with as far, the type of solids and liquids also can differ in which way it gets to separated by us. For instance, it can be difficult to separate oily liquids because the solids are more likely to become oiled straight and therefore adhere harder. Finally, the temperature and acidity/pH of the mixture may play a role in how well such mixtures can be separated. By simply tweaking these variables, we are often able to enhance our ability to separate solids from liquids.

Solid-liquid separation is applicable for a number of important processes which belong to different industries. It is employed in the food industry to filter pulp from juice, sever curds from whey in cheese production or clarify wine and beer so they are clear and delicious for consumption. Pharmaceutical: Solid-liquid separation in the pharmaceutical business is essentially applied to cleansing or purification of medication and antibodies for human utilization.

It is a process utilized in the mining sector to separate precious minerals from waste rock so that relevant resources can be extracted. In oil and gas, solid-liquid separation aids in the cleaning of crude oil by removing unwanted impurities. Finally, within the wastewater treatment industry this process is necessary to filter out contaminants from soiled water before it can be allowed back into their natural environment and thereby keeping safe our precious source of fresh clean drinking water.

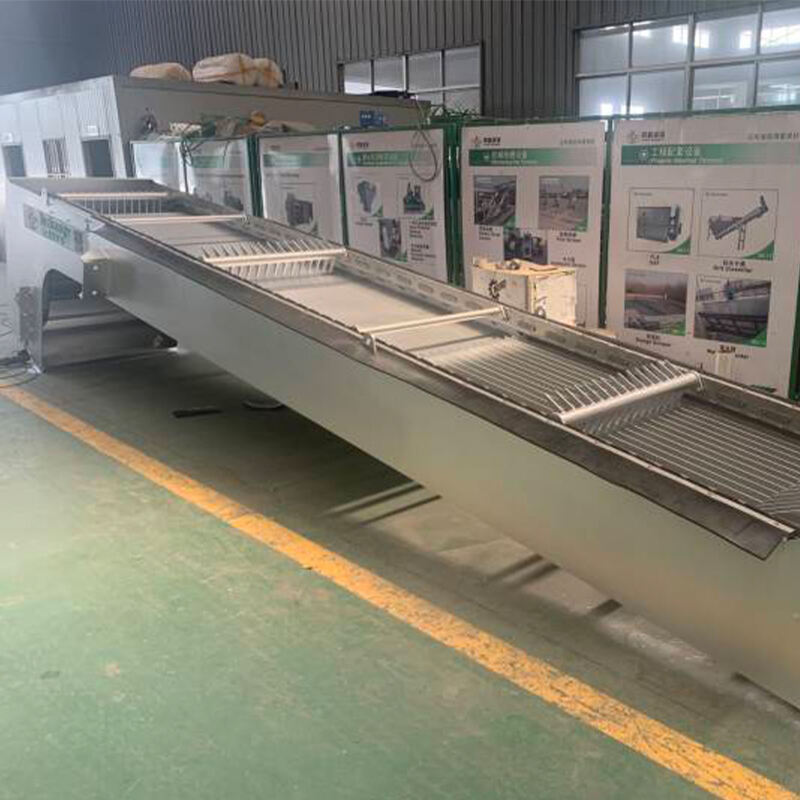

machines are ISO 9001, SGS, certified. solid and liquid separation the engineering design, technical staff will offer rational suggestions on selection of products the user and designer of the project in order to ensure that the advantages of each machine when it comes to the construction of the project maximised.

will meet your needs and those of relevant specifications. will plan and build solid and liquid separation and equipment in a superior way and will check the quality of equipment purchased.The product will be covered with a 1-year warranty free. After that, customer is able to continue receiving after-sales support for as long as they like with only the cost.

Our CNC machine laser cutting and bending are at forefront of technology that allows us to ship our products in time and according to your requirements.Our team is made up of highly educated professionals with advanced degrees in environmental science, engineering other related fields. Many staff members possess over 10 years of experience in research and development. have developed numerous patents for company.

Jiangsu Techange Environmental Sci-Tech Co., Ltd., established on October 8 in 2008. Since 2009, we've been specializing exportation wastewater solid and liquid separation machines. We are a professional producer designer of water treatment equipment that is situated in Yangzhou, Jiangsu, China. We are well-known in Europe, North America and Asia.