Tel: +86 17715878828

Cellphone & WhatsAPP:+86 17715878828

Email: [email protected]

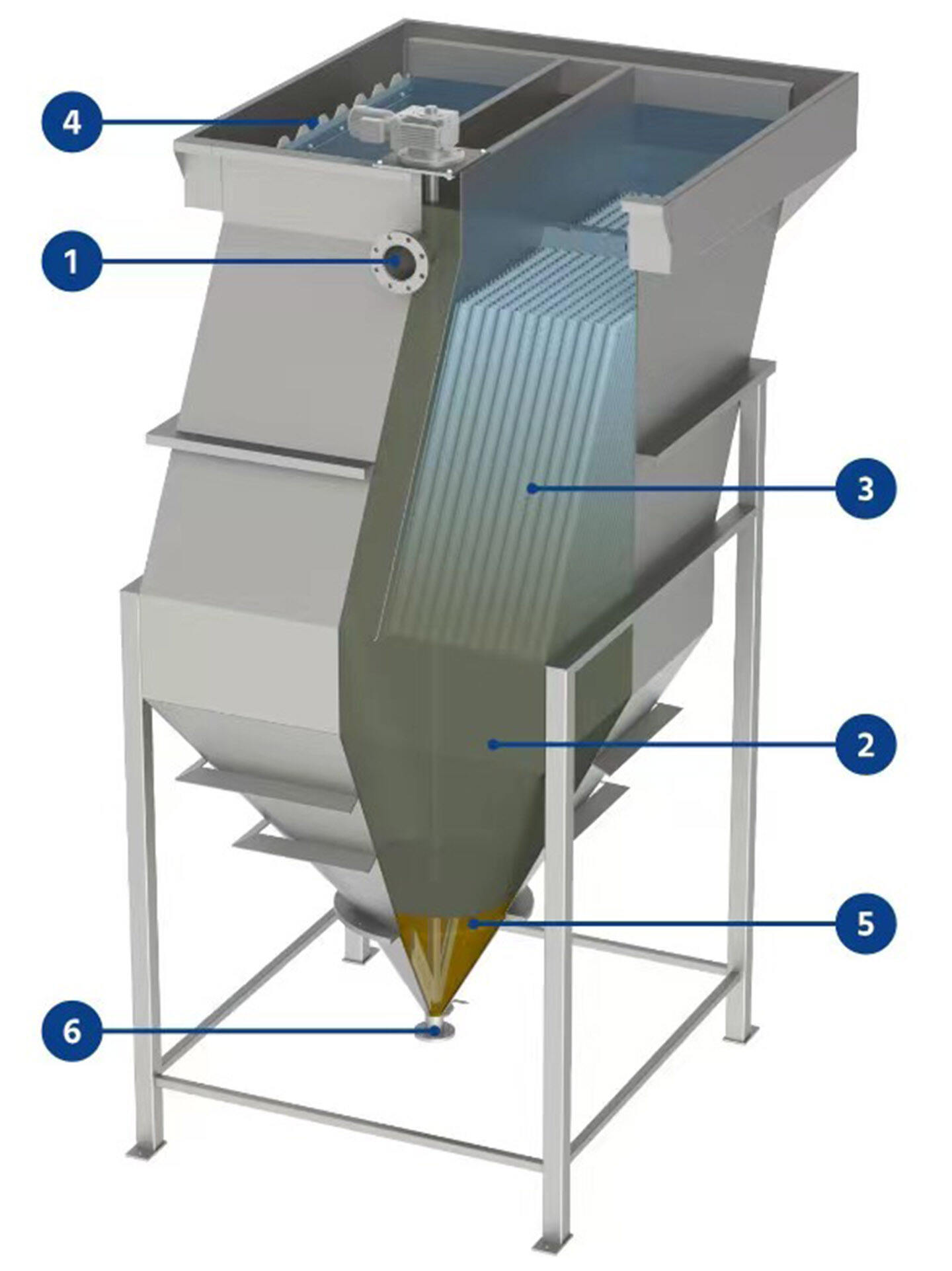

Lamella clarifier is an efficient combined sedimentation tank, According to the shallow theory designed;Many dense inclined plates are set in the subsidence area to allow suspended solid in the wastewater to settling on the inclined plate. Water rises and flows upon the inclined plate .The separated sludge slides down the inclined plate to the bottom of the tank under the effect of gravity. Sludge can be discharged in a collector, which can increased capacity by 3 to 5 times on the same area. According to the test data of raw wastewater, different flow rate precipitators can be chosen.

HOW DOES LAMELLA CLARIFIER WORK

When using, you can choose to add coagulant. The method is to install inclined plate component with an inclination angle of 60 degrees above the suspended layer of sludge. Suspended solids in the raw water, solids or floc alum flowers formed by adding a coagulant are added to the surface area of the inclined plate Accumulate into a thin mud layer, rely on gravity to slide back to the suspended sludge layer, and then sink into the mud hopper. The sewage pipe is discharged into the sludge tank for further treatment or comprehensive utilization. The supernatant gradually rises to the drain of the water collection , which can be directly discharged or reused.

RANGE OF APPLICATION

Mining Metal finishing Treat groundwater Industrial process water

Backwash from sand filters Pre-treatment ahead of membrane filters

Municipal wastewater TSS, solids/particulate removal

Dissolved solids and metals precipitation Leachate clarification

Cooling tower water clarification Surface/raw water treatment

Water recycling/reuse

ADVANTAGES

Smaller footprint

Large effective settling area

Improved overflow rates 2 to 4 times

Long time to be use

Normal use without clogging

Even clogging is provided with backwash device Less possibility for injury

AVAILABLE DESIGNS

Inclined plate length 1–2 m Plate pitches between 50° and 60°

Allow for self-cleaning, pitches require backwash Loading rates are 5 to 15m/h

Set up scraper for easy drainage.

SPECIFICATIONS

| Capacities(m/h) | Piping Connections() | Physica| Dimensions(m) | |||||

| Inlet(a) | Effluent(b) | Sludge(c) | Backwash(d) | L | W | H | |

| 5 | 80 | 80 | 50 | 50 | 2.55 | 1.6 | 2.9 |

| 10 | 100 | 100 | 50 | 50 | 3.35 | 1.82 | 3 |

| 15 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| 20 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| 30 | 150 | 150 | 50 | 50 | 4.2 | 2.22 | 3 |

| 40 | 150 | 150 | 50 | 50 | 4 | 2.8 | 3 |

| 50 | 200 | 200 | 50 | 50 | 4.65 | 2.82 | 3 |

| 60 | 200 | 200 | 50 | 50 | 4.7 | 3 | 3 |

| 70 | 250 | 200 | 50 | 50 | 6.4 | 2.6 | 3 |

| 80 | 250 | 200 | 50 | 50 | 6.8 | 2.82 | 3 |

| 100 | 250 | 250 | 50 | 50 | 7.05 | 3.02 | 3 |