Tel: +86 17715878828

Cellphone & WhatsAPP:+86 17715878828

Email: [email protected]

The purification process of sewage is a process of substance transformation. Many soluble substances are transformed into suspended solids after physicochemical or biochemical treatment, and then become sediment or floating solids, so that the solid substances with water can be separated from the water. The separation of mud and water can generally refer to the separation of sediment from the bottom (including some floating materials).

Sludge water separation equipment (also known as sludge and slag discharge equipment) mainly refers to the equipment used in various water treatment process components such as sedimentation tank, sludge tank, thickener, etc., which is responsible for large area scraping and discharging of sludge at the bottom of the tank. The water content of sewage sludge varies depending on the process conditions, so it can be considered as the pretreatment equipment of wet sludge dewatering equipment. It can also refer to multi-functional combination devices that expand the process, such as reaction precipitator, biochemical reactor accelerated clarifier, sludge scraper, integrated water purifier, etc. Which can more effectively collect and separate solids or foam in water.

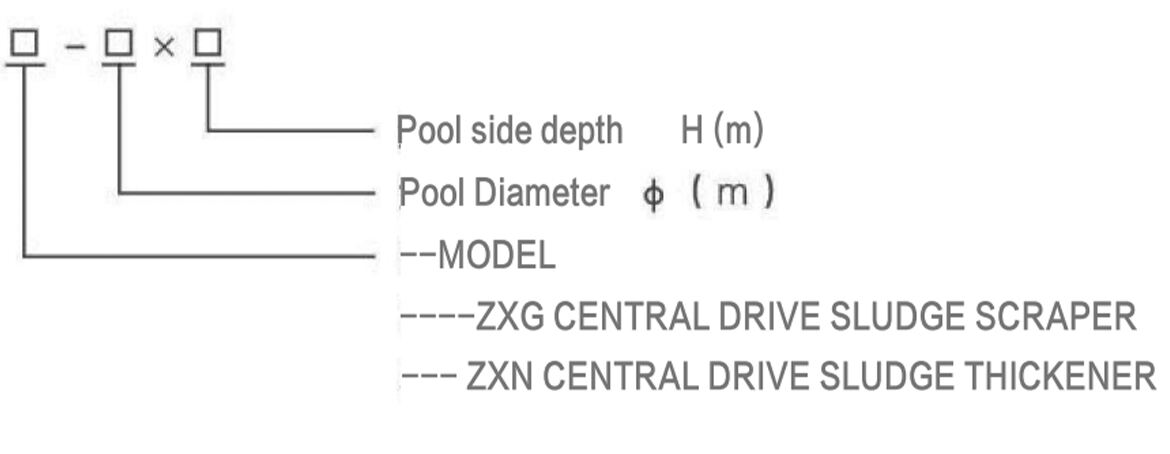

ZXG 、 ZXN

CENTRAL DRICE SLUDGE SCRAPER, THICKENER

APPLICATION

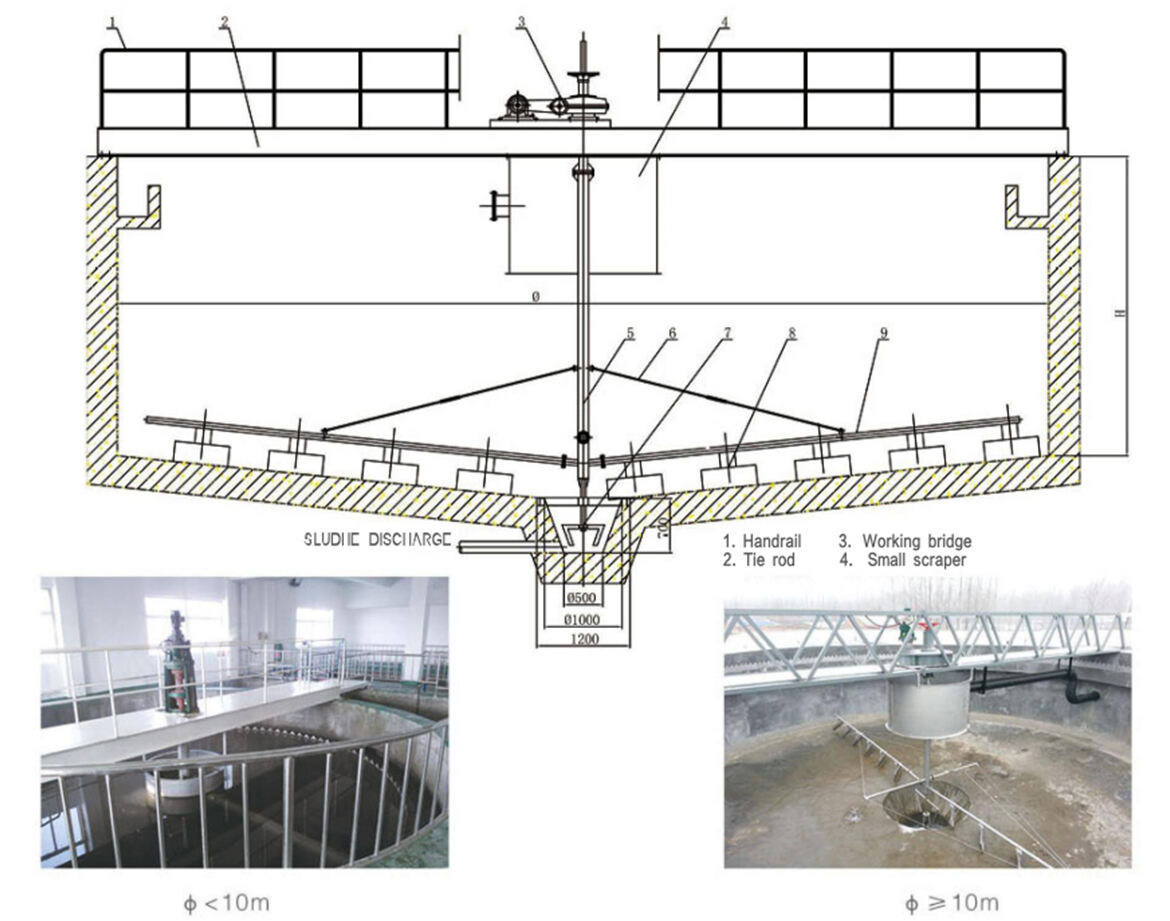

The central drive structure is generally used to scrape the bottom mud of various circular sedimentation tanks with a tank diameter of less than 18m (generally, the water site of a single tank is less than 600T/h). Normally, the sludge is discharged from the center, and water outlet from besides.

ZXG central drive mud scraper is generally used for municipal sewage and similar sewage (such as petrochemical, paper making and other industries). The proportion of sludge is relatively light (generally less than 1. 2T/m 3), which is not easy to harden the bottom sludge of the pool. Generally, there is no scum scraping function. Inclined plates or pipes can be set in the pool to improve the sedimentation effect.

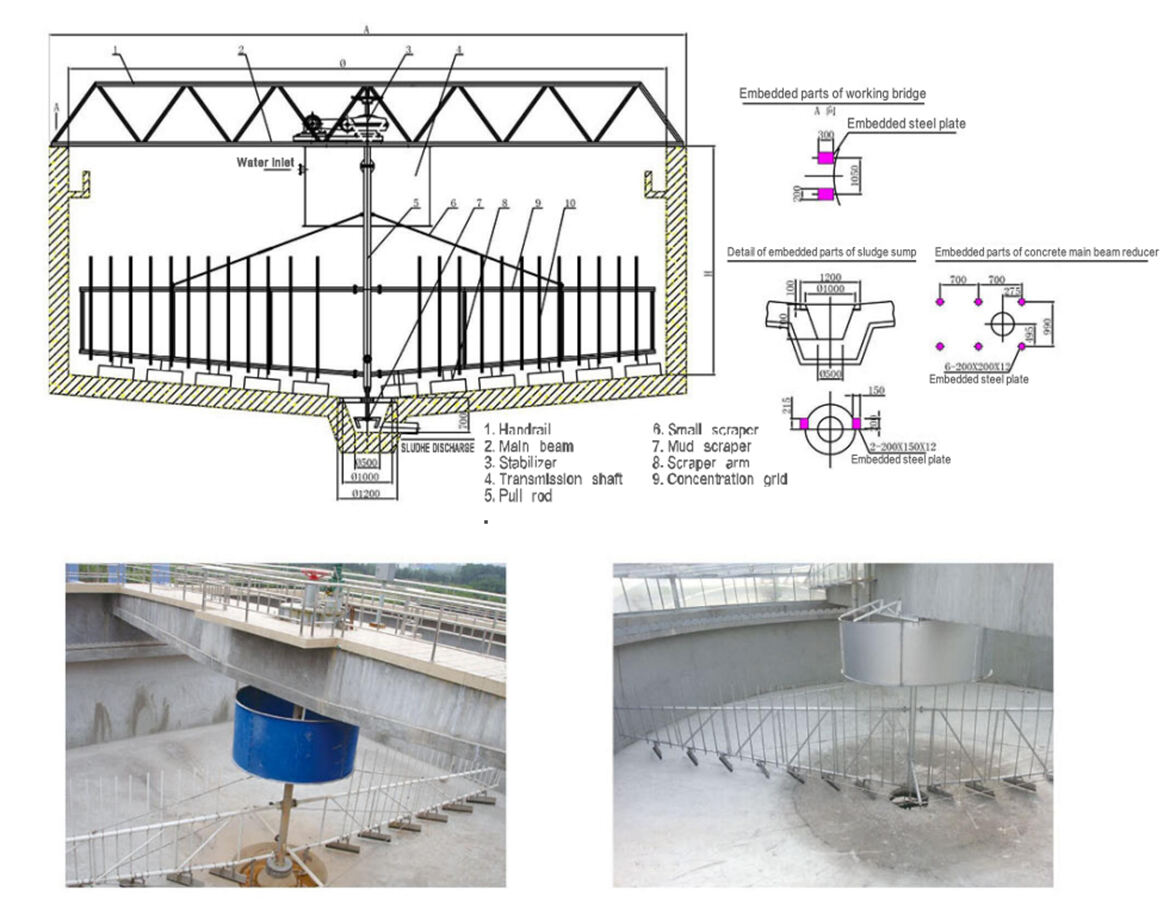

ZXN type central drive thickener is basically similar to ZXG type thickener. It is mainly used to further concentrate the sludge discharged from the ordinary sedimentation tank. In structure, the grid section is added to the sludge scraper (to increase the sludge compactness).

Working bridge structure: profiled steel beam shall be used for the pool diameter below 10m, and split frame beam shall be used for the trunk of 10m.

MODEL INDICATION

ADVANTAGE

1. Generally, it is larger than the three-stage cycloidal reduction drive. For large torque (generally more than 10000N/. m), the slewing ring structure should be used. The drive is stable, and the torque adjustment is convenient and safe.

2.The rake arm angle can be set to adapt to different slope bottoms (e.g. i=1: 10}), and the rake can be lifted manually

3.The function can be expanded, such as adding torque control indicator and automatic rake lifting structure.,

4.The mud scraper adopts a rubber composite structure, which can scrape mud thoroughly.

5.The structure is simple, and the installation and use are convenient. The steel drum thickener is supplied in thousands of complete machines.

Ordering Instructions

1. The model shall be selected reasonably according to the application situation, and the model, specification, pool diameter, pool depth and other parameters shall be specified in detail.

2. When ordering, indicate the material requirements and scope of supply.

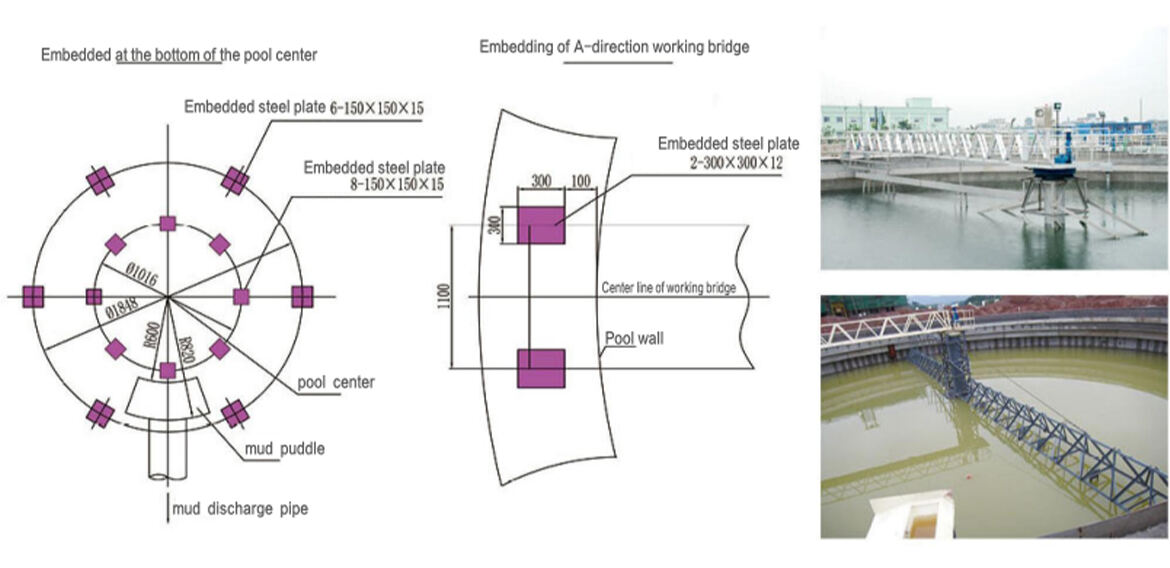

3. The concrete working bridge shall be embedded according to the corresponding dimensions in the drawing.

4. Specific parameters can be obtained separately, and the supplier may place an order.

PARAMETERS

| CHANNEL DIAMETER (m) | OUTER EDGE LINEAR VELOCITY(m/min) | POWER(kw) | SUGGESTED CHANNEL DEPTH (m) | SUGGESTED CHANNEL GRADIENT(i) | |||

| ZXG | ZXG | ZXG | ZXG | ZXG | ZXG | ||

| 3.6; 4;4.5 | Primary sedimentation tank; 2~3; Secondary sedimentation tank 1.5~2.5; | ≤2 | 0.37 | 0.37 | 2.5 | 1:12 | 1:10 |

| 5 | |||||||

| 6 | 0.55 | 0.55 | |||||

| 7 | 3 | ||||||

| 8 | |||||||

| 9 | |||||||

| 10 | 0.75 | 3.5 | |||||

| 12 | 0.75 | ||||||

| 14 | |||||||

| 16 | 2| 1.5 | |

|||||

| 18 | 1.1 | ||||||

| 20 | |||||||

ZXG SHAPE STRUCTURE

ZXN SHAPE STRUCTURE (ZXN4-14)

ZXG Shape Structure

| PARAMETER / MODEL | BASIC SIZE(mm) | CHANNEL BOTTOM SLOPE (1) | RAKE LIFING HEIGHT (mm) | ||

| CHANNEL DIAΦ | A | B | |||

| ZXN-15 | 15000 | 15100 | 1250 | 1:12 | 200 |

| ZXN-16 | 16000 | 16100 | 1250 | ||

| ZXN-18 | 18000 | 18100 | 2000 | ||

| ZXN-20 | 20000 | 20100 | 2000 | ||

ZXN SHAPE STRUCTURE (ZXN1 5-20)

Transmission Structure

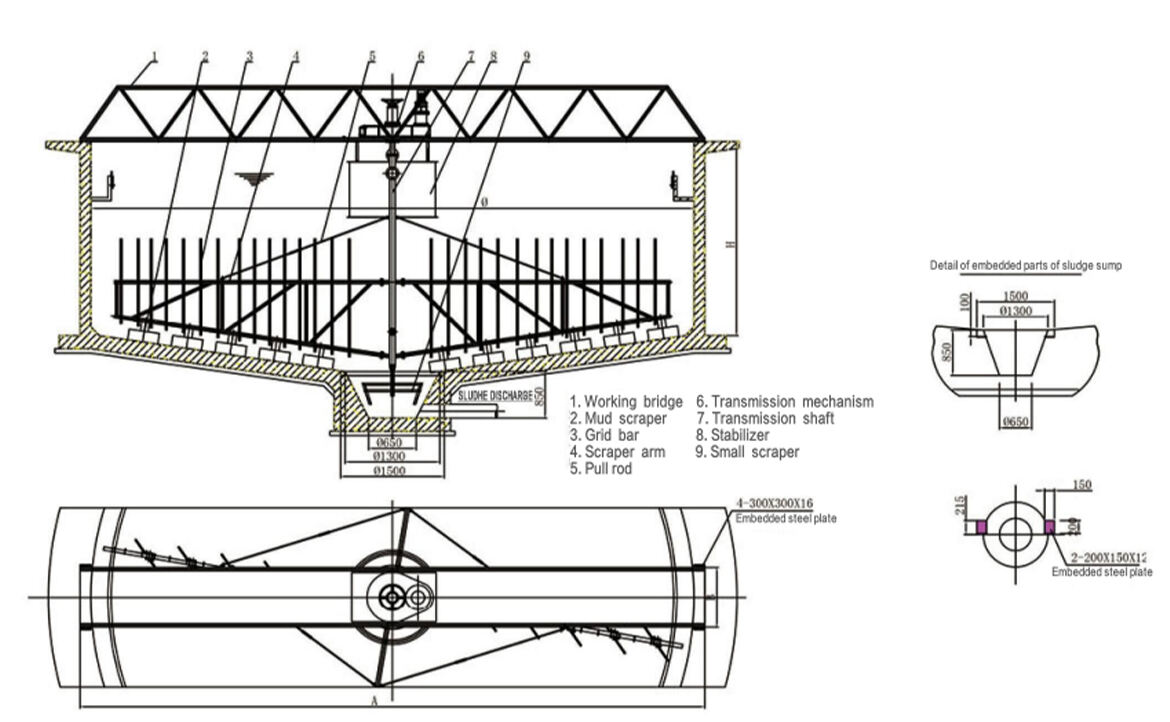

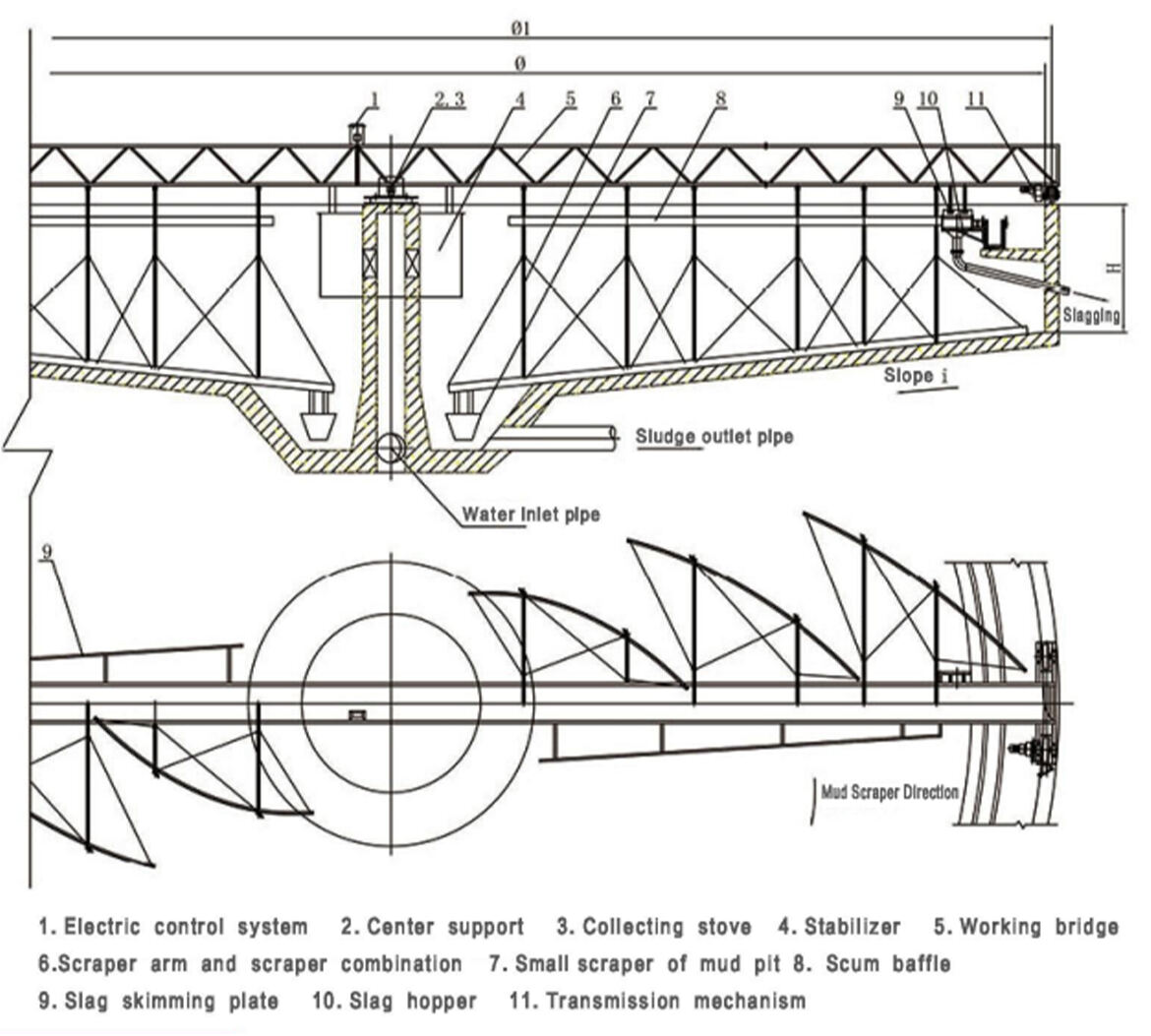

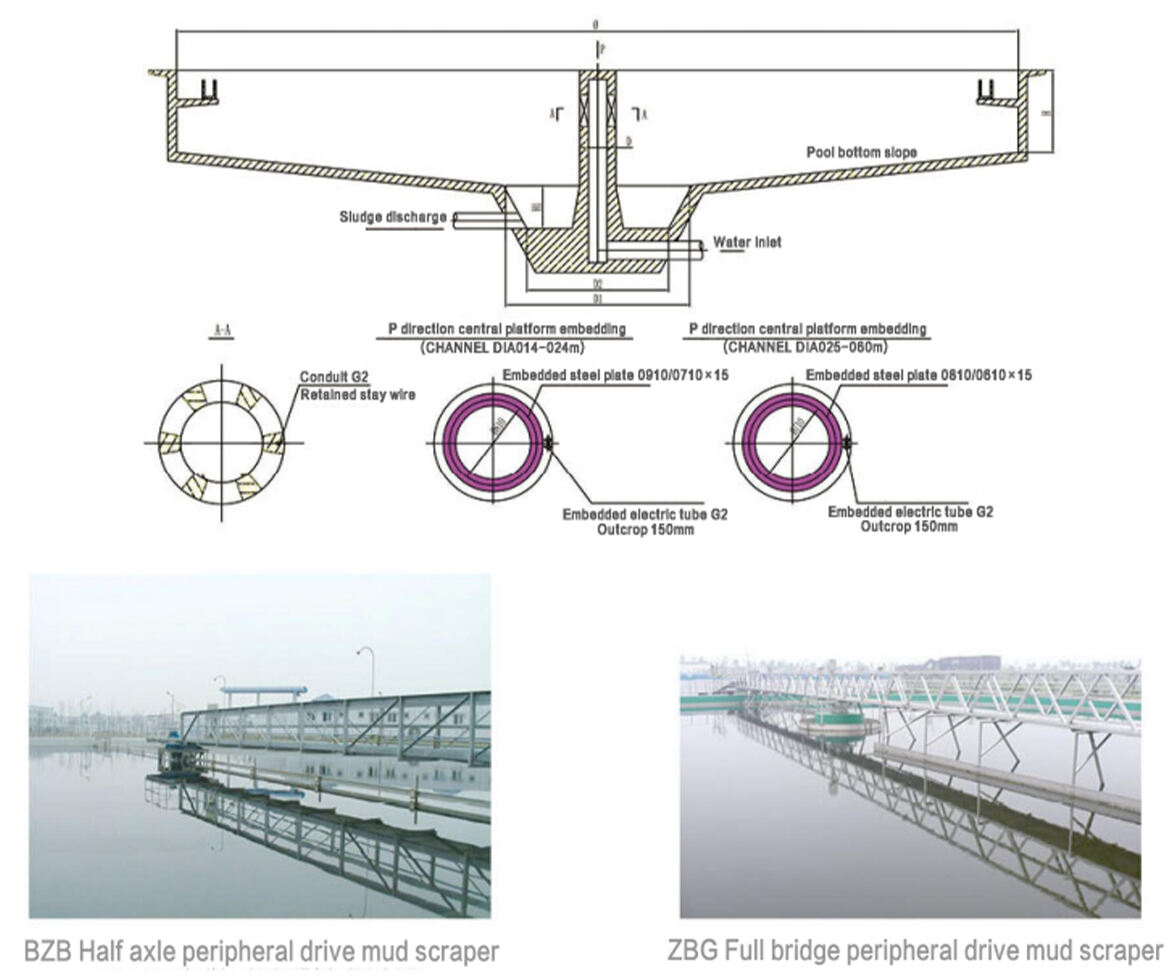

ZBG/BZBG

Peripheral Transmission Mud Scraper

APPLICATION

ZBG/BZBG1 Peripheral drive mud scraper is mainly used in the primary sedimentation tank and secondary sedimentation tank of large sewage plants (generally, the water site is more than 600m3/h, and the tank diameter is more than 20m). The sludge at the bottom of the scraping basin (the specific gravity is generally less than 1.2, and it is not easy to harden). Generally, there is no scum (or foam) scraping system at the upper part, which has the functions of mud scraping and scum scraping. The process is generally central water inflow, peripheral water outflow, and central sludge discharge.

MODEL INDICATION

ADVANTAGE

1. The supporting wiper is used for overload protection, and the operation cost is effectively reduced.

2. The working bridge normally adopts the detached girder, with light weight, good rigidity, and the bridge length can be determined according to the process requirements.

3. Logarithmic spiral mud scraper, without roller at the bottom, effectively prevents jamming.

Ordering Instructions

1.The model and specification, pool side depth, pool bottom slope and other parameters shall be indicated. If it is not indicated, the order shall be made according to the table value of half bridge.

2. The central flow stabilizing cylinder, scum baffle (pupil plate), scum scraping device, slag bucket (including slag discharge pipe), water outlet (non concrete), electric control box, track and its accessories (non rubber wheel) and all embedded parts shall be ordered separately.

3. The materials include underwater stainless steel (304), working bridge (aluminum alloy, stainless steel), walkway plate (stainless steel, glass fiber reinforced plastic), baffle plate and weir plate (stainless steel, glass fiber reinforced plastic, and flow stabilizing cylinder (stainless steel, glass fiber reinforced plastic). If no material or anti-corrosion requirements are specified, it means that the order is made according to carbon steel and ordinary anti-corrosion.

4. There are two types of reducer (imported and domestic): shaft mounted type and horizontal cycloid type for selection, and it is not indicated to order as horizontal domestic cycloid or planet.

5. Any function expansion of the rated power and speed corresponding to the allowable torque value of all equipment shall be ordered separately (for example, the number of rake arms increases, automatic rake lifting, water outlet cleaning brush, etc.).

6. Requirements shall be put forward for different pool bottom slopes, pool depths or other pool structures, and data shall be obtained separately for ordering of commercial equipment.

Outline structure of ZBG sedimentation tank peripheral drive mud scraper (full bridge type)

Technical Performance

| MODEL | CHANNEL DIA Φ(m) | Peripheral linear velocity (m/min) | Unilateral power | P or P/F(KN) | Wheel edge diameter (or gauge) Φ1(mm) | Suggested Channel Depth H (m) | Recommended pool bottom gradient (i) ZBG |

| ZBG-14 | Φ14 | 2-3 | 0.55/0.37 | 18 | 14400 | 3 | 1:12(1:10) |

| ZBG-16 | Φ16 | 16400 | |||||

| ZBG-18 | Φ18 | 0.75/0.37 | 20 | 18400 | |||

| ZBG-20 | Φ20 | 25 | 20400 | ||||

| ZBG-24 | Φ24 | 35 | 24400 | ||||

| ZBG-25 | Φ25 | 40 | 25400 | ||||

| ZBG-28 | Φ28 | 50 | 28400 | ||||

| ZBG-30 | Φ30 | 1.1/0.75 | 60 | 30400 | |||

| ZBG-35 | Φ35 | 75 | 35400 | ||||

| ZBG-40 | Φ40 | 80 | 40400 | 3.5 | |||

| ZBG-42 | Φ42 | 82 | 42400 | ||||

| ZBG-45 | Φ45 | 1.5/0.75 | 86 | 45400 | 4 | ||

| ZBG-55 | Φ55 | 95 | 55400 |

ZBG Dimension Parameters

ZBG/BZBG SIZE DATA

| MODEL | SIZE | Φ | D | D1 | D2 | H1 | L1 |

| ZBG/BZBG | Φ14000 | Φ1100 | Φ2500 | Φ2200 | 700 | ||

| Φ16000 | Φ1100 | Φ2600 | Φ2300 | 750 | |||

| Φ18000 | Φ1100 | Φ2800 | Φ2300 | 800 | |||

| Φ20000 | Φ1100 | Φ3000 | Φ2500 | 800 | |||

| Φ24000 | Φ1200 | Φ3400 | Φ2900 | 850 | 1500 | ||

| Φ25000 | Φ1200 | Φ3500 | Φ3000 | 900 | 1500 | ||

| Φ28000 | Φ1200 | Φ3800 | Φ3250 | 1000 | 1500 | ||

| Φ30000 | Φ1200 | Φ4000 | Φ3400 | 1100 | 1500 | ||

| Φ35000 | Φ1200 | φ4500 | Φ3850 | 1200 | 2000 | ||

| Φ40000 | Φ1500 | Φ5000 | Φ4300 | 1300 | 2500 | ||

| Φ42000 | Φ1500 | Φ5200 | Φ4400 | 1350 | 2500 | ||

| Φ45000 | Φ1500 | Φ5500 | Φ4700 | 1400 | 2500 | ||

| Φ55000 | Φ1500 | Φ6000 | Φ5000 | 1500 | 2500 | ||

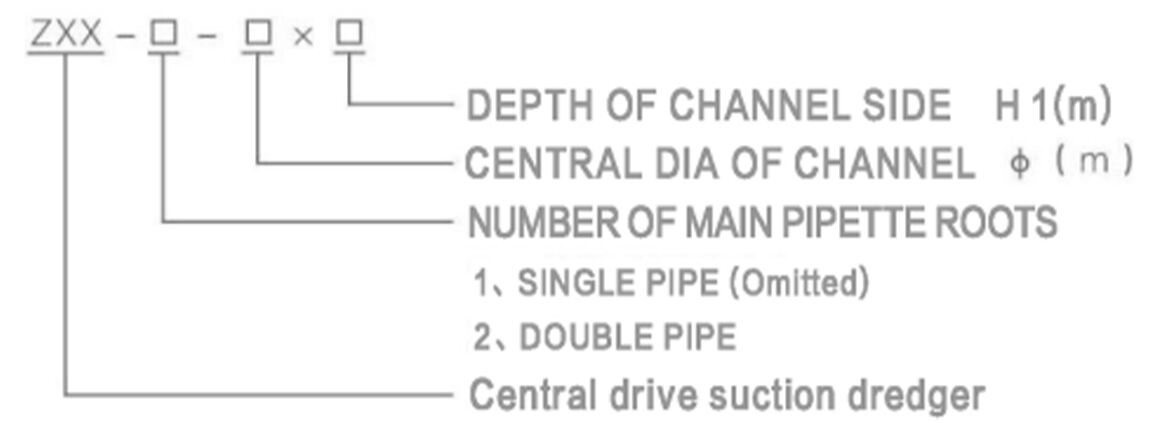

ZXX

Central drive single (double) pipe suction dredger

APPLICATION

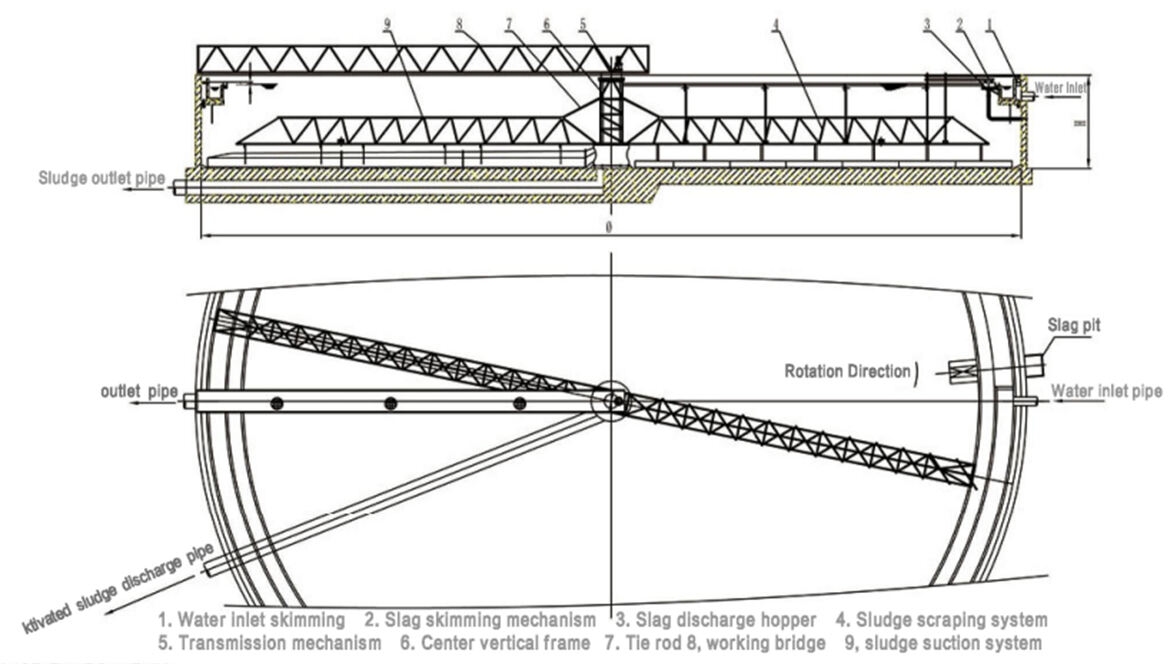

The function of ZXX is basically similar to ZBX peripheral drive suction dredger, which is a new product developed by absorbing foreign technology. The working performance is superior to the peripheral drive type. Generally, the peripheral inlet water and peripheral outlet water are used. The sludge is sucked to the center of the pool by single pipe or double pipe, and then discharged by the sludge valve outside the pool. It can be equipped with scum scraping device (including water distribution tank) to collect inert sludge and activated sludge layer by layer and discharge them.

MODEL INDICAITON

ADVANTAGE

1. The surrounding water distribution is checked by hydraulic model, and the water distribution holes are designed according to uneven distribution, with reasonable water distribution and high sedimentation efficiency.

2. The central buttress adopts steel structure, which reduces the construction difficulty and ensures the transmission accuracy.

3. The sludge suction pipe of the vertical frame is weighted reasonably, and the operation is stable and reliable.

4. The liquid level and flow site can be adjusted or controlled.

5. The new transmission device has large transmission torque and can be controlled or overload protected.

6. The sludge collection pipe and scraper series are designed for specific purpose, and the sludge is completely scraped and discharged.

Shape structure and hydraulic model

Technical Performance

| Parameters Model | CHANNEL DIA (m) | Peripheral linear velocity (m/min) | Motor power (KW) | Recommended pool depth (m) | Minimum settling speed (surface load) (mm/s ) | Water distribution head h(mm) | Internal difference of water distribution ΔH(m) |

| ZXX-25 | 25 | 3-4.5 | 0.37 | 3.5 | 0.3-0.5 | ~100 | ≤50 |

| ZXX-36 | 36 | ||||||

| ZXX-40 | 40 | ||||||

| ZXX-42 | 42 | 0.55 | |||||

| ZXX-50 | 50 |

The water distribution faucet in the table refers to the height difference

between the average water level of the distribution tank and the water level in

the pool

The water distribution internal difference in the table refers to the maximum and minimum water level difference in the distribution tank

Civil Embedded Parts

Ordering Instructions

1. Reasonably select the model according to the application scope and process requirements, and indicate the model and specification, the number of suction pipes for pool depth and other parameters. If it is not indicated, it means ordering according to the table value.

2. Electric cabinet, spray plate, weir plate, water retaining skirt, slag bucket, scum scraping device, groove cleaning brush (fixed and electric), torque indicator and control device, all embedded parts, sleeve valve (movable and electric) shall be ordered separately.

3. When ordering, specify the material requirements.

4. The process requirements (maximum and minimum 'average flow mechanism, pool diameter, reflux ratio, etc.) can be provided for the change of pool structure or the checking calculation of water distribution, and the order can be negotiated.

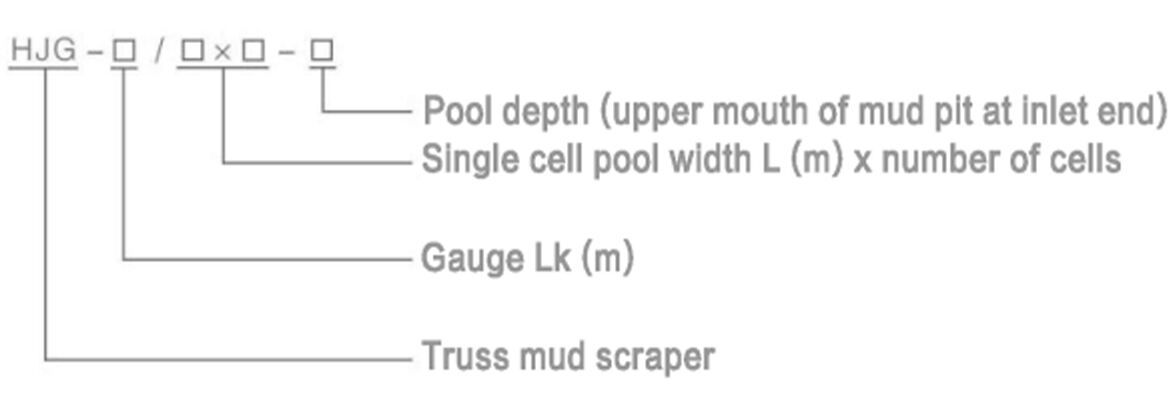

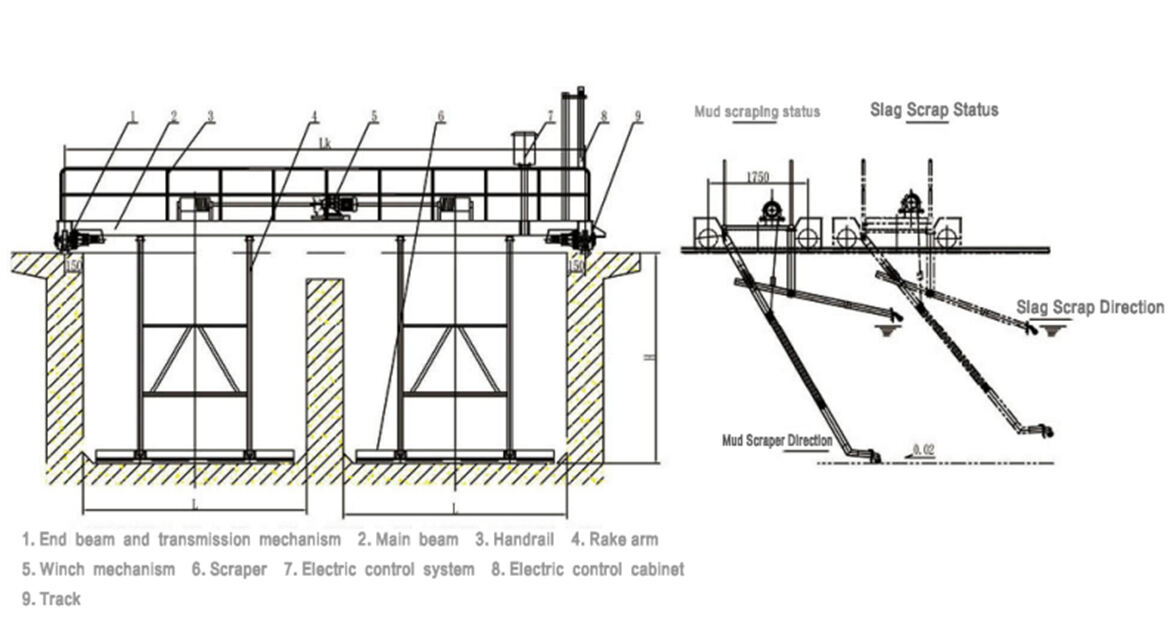

HJG

Truss mud scraper

APPLICATION

The HJG Truss mud scraper adopts reciprocating action to scrape the bottom mud to the sludge sump at one end and discharge it outside. It is used to scrape the sludge at the bottom of the horizontal sedimentation tank. One end enters the water and the other end leaves the water. The tank bottom has a certain slope (about 8/1000). The gauge is generally about 4-25m. When the tank width is large, it can be made into a shared structure with multiple tanks. The gauge is 4-7m. Generally, it is single drive

When the upper part is equipped with water surface oil scraper or foam scraper, it is very similar to HYZ oil scraper and slag scraper in structure and function, but the load is different.

Model

ADVANTAGE

1. It can automatically scrape in layers without jamming.

2. When variable speed transmission is adopted, fast return function can be realized.

3. PLC automatic operation (full stroke or half stroke operation) can be realized.

4. With rake lifting function, load reduction or one-way mud scraping can be realized.

5. When the span is large, synchronous motor is generally used, and rail climbing will not occur.

6. The mud scraper is equipped with rubber plate and roller, and the mud scraper is complete and reliable.

HJG Shape Structure (LK=103-20.3)

Technical Performance

| Parameter Model | Traveling power (KW) | Winch power (KW) | Travel speed (m/min) | Lifting speed (m/min) | Recommended pool depth (m) | Supporting light rail (kg/m) | Rake lifting height (mm ) |

| HJG-4.3 | 0.37 | 0.4 | 1.0 | 0.85 | 3.5 | 15 | ≥200 |

| HJG-5.3 | 0.37 | 0.4 | |||||

| HJG-6.3 | 0.75 | 0.4 | |||||

| HJG-7.3 | 0.75 | 0.4 | |||||

| HJG-8.3 | 0.75 | 0.8 | |||||

| HJG-10.3 | 0.55x2 | 0.8 | |||||

| HJG-12.3 | 0.55x2 | 0.8 | |||||

| HJG-15.3 | 0.75x2 | 0.8 | |||||

| HJG-20.3 | 0.75x2 | 0.8 | 22 |

Ordering Instructions

1. The model shall be selected reasonably according to the application situation, and the model, specification, pool width, pool length and elevation parameters shall be specified in detail.

2. When ordering, the material requirements and supply drawings shall be indicated.

3. Specific parameters can be obtained separately for ordering.

PROJECT REFERENCE