Hello, parents and kids! This post where we are talking about drum screen filter. They serve as, I suppose you might say, huge filters that the water goes through to help make it safe and clean. Let us take you through everything there is to know about drum filter screens, the different categories in which they matter a lot and how correct maintenance can help ensure that your damper filters work at their best.

Image: Think of a drum screen filter as the equivalent to an action hero-using technology based on superheroes to keep waste stream free. Imaging enjoying some lovely lemonade, after taking to the time making it, but first you need to make sure that all the pulp is filtered out of your drink; this is exactly what happens in action courtesy a cool system known as drum screen filter. These screens have obstructors that allow water to flow and are put in a large circular drum with tiny holes. This allows the water to flow through screen into drum and do not allow any waste or dirty water from it, targetted clean = crystal clear.

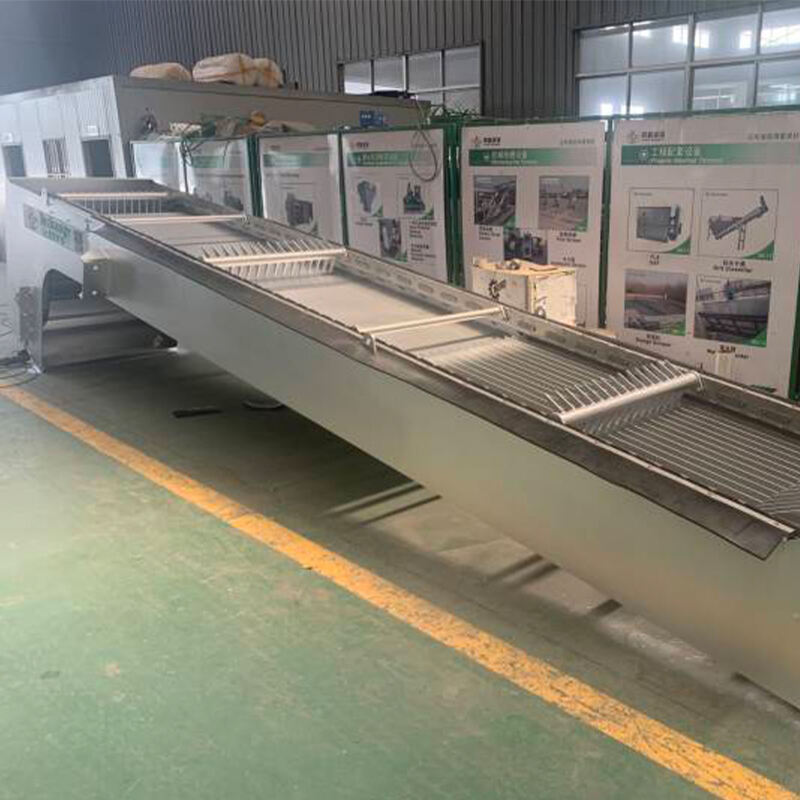

Drum Screen Filter: is a versatile product in the Industrial Market.

This drum screen filter have an enormous extension in the food and beverage business sector, close as a flexible entertainer who plays best in: Food & Beverage Processing Pharmaceuticals Mining A nonstop production process requires clean water supply which is key on these areas. One of the main advantages of a drum screen filter is that its usage helps prevent blockages from forming in pipes or equipment on your premises. In addition to that, these filters are set up in a way protection against solids and other particles which can cause operational issues on your equipment hence it helps with efficiency reducing downtime as well expensive repairs.

If you do not automate, it is a labor-intensive saunter to the tin er for this massive water filtration used by struggling industrial humans. This is where automated drum screen filter systems come to save the day. They are systems that do not work autonomously, being necessary to adjust the filtration according to the pressure at low tide and these sensors are placed in line with the water output. Automating the traditional treatment processes in a lower cost, these automatic systems guarantee crystal clear water without needing constant intervention of man or woman and adapt well to technical conditions from any industrial plant.

This is exactly what the drum screen filters at wastewater treatment plants are responsible for doing, they act as a preliminary barrier in removing solids from water flows before it undergoes subsequent sanitary processing. With an extensive array of screen sizes and flow rates in each drum screen filter, it is important that you select the best operating unit suitable for your wastewater treatment. A fine mesh filter is more likely to get clogged up, but not capturing solids is the tradeoff from a coarser grade. The efficiency of the wastewater treatment process relies on selecting a proper filter to match in accordance with each application.

A drum screen filter is like any other equipment and therefore, requires some sort of maintenance to perform at its optimum condition. The first thing to do is change the filter as needed. Additionally it is also important to have the screens cleaned appropriately wherein they are free of solid composites. In addition, the cleaning method and product type of each manufacturer is crucial to avoid damaging those screens. Testing the sensors and automation, but which must be checked every so often if in working order Investing time on appropriate maintenance methods can maintain the drum screen filter to life or kicking- and also this helps protect your investment making certain that it proceeds running appropriately.

The drum screen filters, finally, are indispensable in numerous sectors and lend themselves to always being used for example. na water treatment plants before reuse Purposes or silt separation. Using strainers - and an understanding of how they work, the advantages of them, as well as what goes into maintaining these important components in a water system helps us to appreciate their contribution to keeping our water clean and units operating. So, here you have it.. choose the appropriate filter and maintain your water well which means never looking back to uncleanly disinfected old filters again for years of service pristine quality drinking water from time in laying doubt aside.

Our CNC laser cutting and bending machines have the latest technology. allows us to supply our products on time in accordance with specifications of our customers.Our team is comprised highly skilled professionals have advanced degrees environmental science, engineering and other related fields. Many team members have over a decade of experience in research and development. Hey have developed numerous patents for our company.

will adhere to demands of your business relevant standards, carefully organize and drum screen filter the processing and production of machines and equipment high-quality, control the quality of the purchased equipment.After the product is accepted after acceptance, it receives a one-year free warranty. After-sales service is provided for life until the warranty is up, and only cost will be to be billed.

machines are ISO 9001, SGS, certified. drum screen filter the engineering design, technical staff will offer rational suggestions on selection of products the user and designer of the project in order to ensure that the advantages of each machine when it comes to the construction of the project maximised.

Jiangsu Techange Environmental Sci-Tech Co., Ltd., founded on October 8 08, 2008. a specialist in wastewater treatment machinery exportation since 2009. firm is a manufacturer and designer of wastewater-treatment machines in Yangzhou, Jiangsu. have already earned an excellent reputation have a drum screen filter market presence in Europe, North America, and Asia.