Lamella thickener is an equipment that helps in cleaning the dirty water. Widespread use is in what are called wastewater treatment plants, which are set up to clean water using any number of methods about 10-20 times a second. Why It Matters Dirty water is bad for plants and animals that depend on rivers, lakes and streams. If we fail to purify the water, it may result in environmental problems. This lesson examines the operation of a lamella thickener and why it makes water clean and safe again.

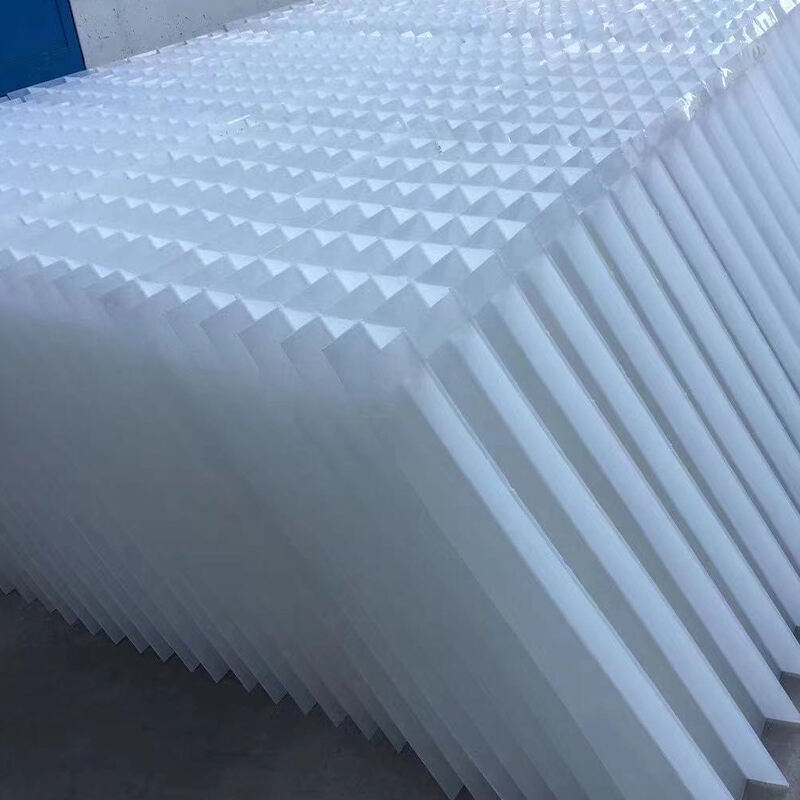

A lamella thickener is an aid in separating solid pieces such as dirt and other particles from water. It employs slanted plates ( i.e inclined surface) to enable the settling of solids down at bottom. These plates are slanted and provide more settlement area for the solids, making them settle quickly. This process of separating the solids from a liquid is known as sedimentation.

It goes like this: the lamella thickener receives dirty water in a first moment. According to its principle when water comes inside, so solid material present in the water drop onto slanted plates. Over time, the heavier and thicker solids settle. These solids are physically pulled to the bottom of the thickener by gravity, clean water rises up. At long last, the clean water leaves through the top of thickener to pass off from solids down at bottom.

What Is actually The Task Of Lamella Thickener? In all of them water should be released from the sludge. After the solids are removed, however, they still have a certain amount of water. This mixture, which is leftover from the disassembling process referred to as mud. Further treatment can remove more water from the sludge. Sludge dewatering, as it is often referred to.

Thickening and dewatering sludge with a lamella thickener can be performed by adding chemicals. These particular chemicals assist with coagulation in that the solid is more bound to 1 another, hence easier for removal from water. Then we add the chemicals and pump it into a belt press. The belt press then applies pressure to squeeze out even more water in the sludge. The end result is a dense, earth-safe cake that will biodegrade once disposed of.

The lamella thickening technology can thus be used in several industries, not only to clean wastewater. It has extensive application in the separation of solids from any liquid. An example from the food industry would be for separating solids with liquids to prepare a variety of foods. It is used in the mining sector to extract minerals and valuable resources from rocks, for example.

Lamella Clarifier vs. Plate Settler the biggest difference between lamellas and plates is that a lamellar clarifier will be able to perform better for smaller particle sizes This is used to remove low volumes of solid from the liquid. This process is vital for sectors that produce huge amounts of wastewater and wish to recycle the water in the future.

will adhere to demands of your business relevant standards, carefully organize and lamella thickener the processing and production of machines and equipment high-quality, control the quality of the purchased equipment.After the product is accepted after acceptance, it receives a one-year free warranty. After-sales service is provided for life until the warranty is up, and only cost will be to be billed.

Jiangsu Techange Environmental Sci-Tech Co., Ltd., established on October 8 in 2008. Since 2009, we've been specializing exportation wastewater lamella thickener machines. We are a professional producer designer of water treatment equipment that is situated in Yangzhou, Jiangsu, China. We are well-known in Europe, North America and Asia.

of machines have lamella thickener ISO 9001, SGS, certified. Before the engineering design, technical personnel will provide reasonable selection suggestions to designer and the user of the project in order to ensure that the advantages of each component for the construction of project will be maximized.

Our CNC laser cutting and bending machines have the latest technology. allows us to supply our products on time in accordance with specifications of our customers.Our team is comprised highly skilled professionals have advanced degrees environmental science, engineering and other related fields. Many team members have over a decade of experience in research and development. Hey have developed numerous patents for our company.