For the motor factory, people make things and it is vital for them to keep solids away from liquids as they do. But how do they exactly perform this? A solid separator A kind of machinery special machine This machine has a significant function to separate what is basically in the form of solids and liquids. Frequently utilized in a wide variety of industries including food, drinks, farming and many other areas. We Very Helpful Mission Now Not Easy Would Use Make Used We Or Those In Quite Day Like To Of Your Drinks And This Eat Things Without Food Most

When it comes to your work, having the right solid liquid separator is very important. Common Separators Rate: **Good for various tasks! If you wish to separate small chips/particles from a liquid, then something like using a filter(Filtering) A centrifuge - For isolating components one not really filterable from a mixture when the only determining factor is density IF you are trying to separate out grease and oil, with greatest efficiency. If you have a suspended solids or slurry, pick a hydrocyclone. Every separator has a unique place, and you should know about each of them in order to make good choices on selecting the right type fits your need!

A Solid Liquid Separator: This Is How Business Owners Can Discover The Savings So here is the deal: If you have a mix of solids and liquids, they should be separated if possible before going to market. Because if you do not — their use in this mixed form is also rather limited and customers might love that. Nevertheless, a solid liquid separator will quickly separate the solids from liquids for convenient handling. It allows you to sell solids and liquids separately, helping operating generate more revenue! Not only that, but you will also save a lot of time as well since separating them by hand can be very long and exhausting.

Hydrocyclone The hydrocyclones are ideal for a situation where there is an amalgamation of liquor and liquid. It utilizes gravity to center the solids and liquids on one side, which effectively separates them.

Settling: It is used when you have coarse solids with high solid content which settle down at the bottom. It will enable all them heavy solids so settle to the bottom, and you can just collect the liquid from top.

Upkeep: This includes keeping your separation equipment in good shape. It is necessary to keep it clean and repair damaged parts frequently; we must also ensure that the lathe works properly without any error.

Optimizing-This involves maximizing the services your separator is providing, You could fine-tune the rates liquids pass through, adjust how hot things get up to be heated in a cooler or use different filtration materials for better outcomes.

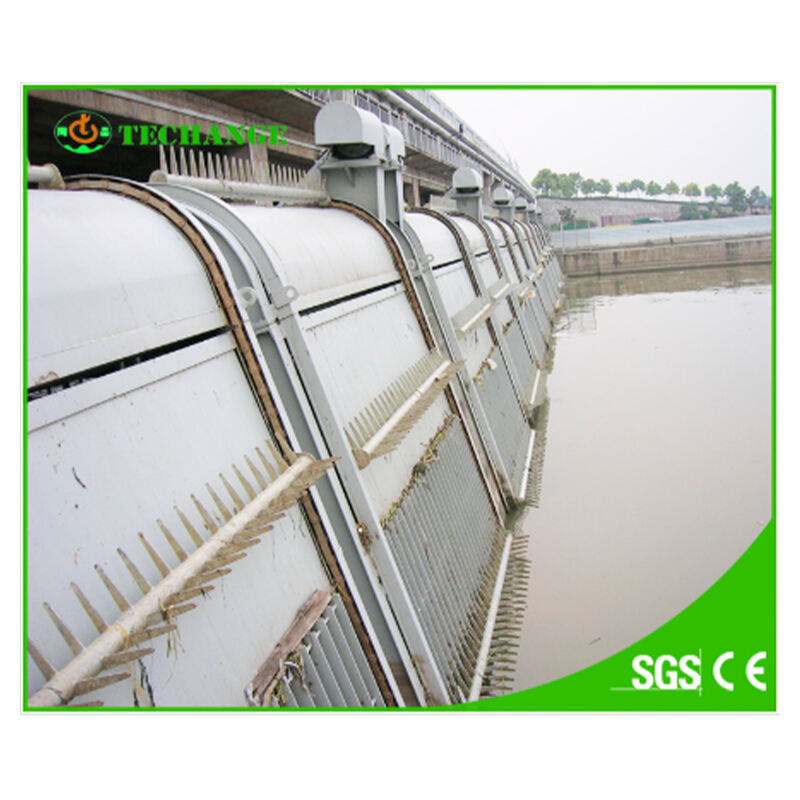

Jiangsu Techange Environmental Sci-Tech Co., Ltd., established on October 8 08, 2008. Since 2009, we've been specializing in exportation of wastewater treatment equipment. We are a reputable manufacturer and designer of water treatment equipment that is located in solid liquid separator, Jiangsu, China. have already gained outstanding reputation and strong market presence in Europe, North America, Asia.

We have advanced laser cutting machine and CNC bending machines, which allow us to provide our customers with the products on time and in line with their specifications.Our team is made up of highly educated professionals hold advanced degrees environmental science, engineering related fields. Many team members have more than a decade of experience working in research and development. have authored numerous patents for our company.

We will meet your needs and the requirements relevant standards. We will plan solid liquid separator machines and equipment in a high-quality manner, and we will control the quality of the purchased accessories.The product is covered by a one-year guarantee free. After that, customer is able continue receiving after-sales services for as long as they like and only pay for the cost.

machines are ISO 9001, SGS, certified. solid liquid separator the engineering design, technical staff will offer rational suggestions on selection of products the user and designer of the project in order to ensure that the advantages of each machine when it comes to the construction of the project maximised.